Basic Hydraulics

Course #

301

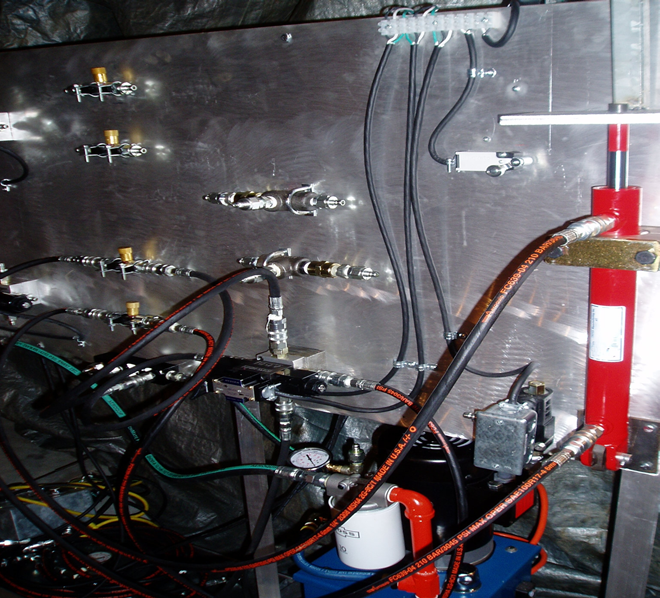

This is an instructor led, competency based program designed for entry level mechanics. The course will introduce mechanics to the fundamentals of Industrial Hydraulic controls. The fundamental hydraulic components such as pumps, hydraulic actuators and accumulators are studied in detail. Each student will get a opportunity to design a hydraulic system and test it on "Automation Studio" a computerized Hydraulic Simulator.

Approved CEU Credits:

3.0 Credits

D.E.P. Approved Course ID #2794

Prerequisite:

The student should have some exposure to hydraulics systems. The student should have worked around mechanical and hydraulic systems for a few years.

Format:

Instructor Lead

Online/Labs

Cost:

$695.00 / Contact us for the Online cost

Learner Outcomes:

- The student will acquire knowledge of basic physics. The student will be able to recognize definitions for force, friction and inertia. Given a problem the student will be able to select proper formulas and perform the calculations.

- The student will acquire an understanding of the Hydraulic Transmission of Force and Energy. The student will be able to use the hydraulic power triangle, recognize a weighted accumulator, draw a static hydraulic system and calculate the force of a cylinder.

- The student will be able to describe atmospheric pressure and its effects on pumping systems. The student will be able to recognize pump cavitation and locate its cause. The student will be able to identify different types of pumps and explain their operation.

- Using a hydraulic diagram, the student will be able to identify hydraulic cylinders and hydraulic motors. The student will be able to explain their operation and calculate the mechanical force that these components can develop.

- Given a hydraulic diagram containing standard ANSI Y32.10 Symbols, the student will be able identify and ex- plain the operation of check valves, two position four way valves, three position four way valves and flow control valves.

- Given a hydraulic diagram, the student will be able to explain all the components and how each are used and what would happen to the hydraulic system if it failed

- The student will be introduced to powerful trouble-shooting techniques and will use these techniques to trouble-shoot a hydraulic system.